Serial Number Tracking Explained

Table of Content

Controlling inventory is a demanding task, and without the use of serial numbers and inventory management software, it can be significantly more difficult. Let's examine what a serial number is, when to use one, and what its advantages are.

What is Serial Number Tracking?

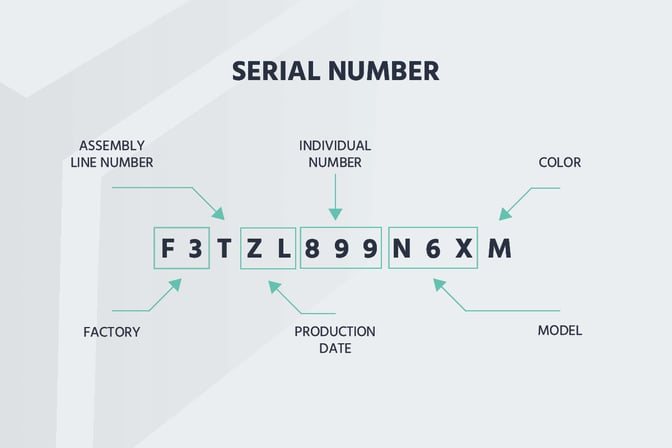

Serial number tracking enables you to follow individual items from their creation until their sale. Each product will have a particular identifying number that will allow you to determine who purchased which product. Keeping track of your inventory could prove challenging without a serial tracking system in place.

The Difference Between Serial Numbers and Barcodes

One could initially assume that there is no significant difference between serial numbers and barcodes. Surely serial numbers make up barcodes? Apart from the fact that they are both made up of numbers, there is a difference between the two.

A serial number is first and foremost a unique identification number you attach to a specific item. Consequently, a single serial number identifies a single item. A barcode on the other hand identifies products with the same qualities. For example, let's say you have a clothes store. There won't be a unique serial number generated for every single t-shirt as you will sell thousands. You have nothing to gain by keeping track of specific items. Therefore, you add a generic barcode to it, such as one for a black L-sized t-shirt.

Why is Serial Number Tracking Important?

Here are the main benefits of using serial number tracking that you should take into account:

Serial Number Traceability

The capacity to track and trace each item back via the supply chain is the most significant advantage of using serial number tracking. Once a product has a serial number, it can be tracked to the end consumer via distribution networks.

This traceability helps with pipelining inventory, post-sale guarantees, and tracing products between warehouses. Serial number tracking also makes it easier to manage consumer warranties since it records a serial number against a specific sale and displays it in a customer's purchase record.

Inventory Control - Protect your profits

Online merchants lose approximately $10 to return fraud for every $100 worth of goods accepted for return. Serial number tracking of products that leave the warehouse makes returns easier to manage as an item’s serial numbers can be checked on return. This also protects you from common return scams, where someone may buy a product and then try to return a different one, robbing you of inventory value.

Which E-commerce Businesses Should Use Serial Number Tracking?

Tracking serial numbers is more important in certain industries than in others. Some examples include the automobile industry, the medical industry, product rentals, and the most common within 3PL, the electronic industry.

Tracking Serial Numbers in the Electronics Sector

Serial numbers can be very important when fulfilling electronics. Electronics manufacturers, distributors, and retailers can trace defective products using serial numbers to pinpoint the particular parts that are faulty.

Within electronics, it is especially important to keep track of warranty details. Businesses can lose a lot of money by offering free services on products with expired warranties or accepting returns of the wrong product when serial numbers are not correctly tracked. On the other hand, they might severely damage customer satisfaction by refusing to offer service for items that still have a valid warranty.

byrd's Software: A Powerful Solution for Your Inventory Management

There is no doubt that technology is essential to inventory management. byrd’s inventory tracking system provides a good way for you to have automatic control over it. Our dashboard gives you straightforward and effective management to grow your business profitably, from purchasing management to stock control.

You can add serial number tracking for your B2C shipments using our all-in-one fulfillment solution by simply adding (or changing) products to your inventory and filling out a serial number tracking property in our dashboard. Once the products are due to be shipped, the warehouse workers scan the serial number of the item to make sure that the correct product is shipped to the customer. If there are returns, you can also keep track of returns to the warehouse with the help of our returns portal.

Simply put, byrd’s serial number tracking solution allows you to keep track of any item in your inventory from the time it is created until it is sold. This function provides your business with crucial insight into the locations of your products, allowing you to relax knowing that the traceability of your order fulfillment is fully taken care of.