Serial Number Tracking Explained

What is Serial Number Tracking?

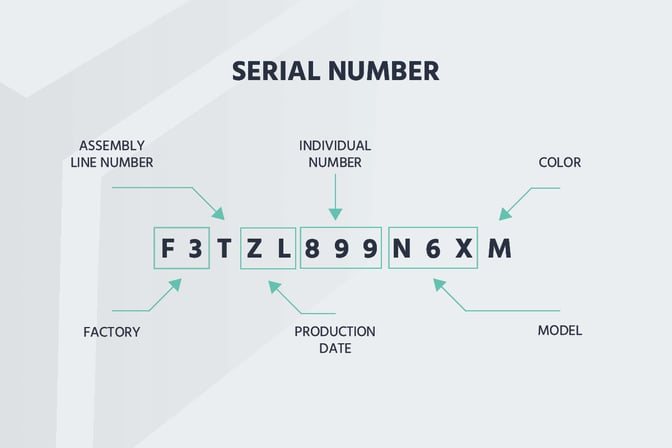

Serial number tracking is a process that enables you to track an individual item from its creation until its sale. Each item will have a unique identification number that will help you in determining who purchased which item. Without a serial tracking system in place, managing your inventory may prove difficult.

The Difference Between Serial Numbers and Barcodes

The first thought might be that there is little distinction between serial numbers and barcodes. Surely barcodes are made up of serial numbers? The two are different, despite the fact that they are both composed of numbers.

A serial number is primarily an identification number that you attach to a particular item. As a result, a specific serial number can be used to identify a specific item. A barcode, on the other hand, identifies products with the same characteristics. Let's say, for illustration, that you run a clothing shop. Since you'll sell thousands of t-shirts, no individual serial number will be created for each one. You gain nothing from keeping track of specific t-shirts. Instead, you'll attach a generic barcode, such as one for a black L-sized t-shirt.

Why is Serial Number Tracking Important?

The following are the main advantages of serial number tracking that you should consider:

Serial Number Traceability

The main benefit of serial number tracking is the ability to follow each item back through the supply chain. Once a product has a serial number, distribution networks can follow it all the way to the customer.

Tracing products between warehouses and pipelining inventory are all made easier by this traceability. Since it associates a serial number with a particular sale and shows it in a customer's purchase history, serial number tracking also makes it simpler to manage consumer warranties.

Inventory Control - Protect your profits

For every $100 worth of products accepted for return, online retailers lose $10 to return fraud. This can be avoided if e-commerce businesses use serial number tracking since each item's serial number can be checked on return and compared with the serial number of the item that was sent to the customer. This safeguards you against widespread return fraud that deprives you of the value of your inventory.

Which E-commerce Businesses Should Use Serial Number Tracking?

In some businesses, tracking serial numbers is more crucial than in others. Examples include the automotive, medical, rental of goods, and the most typical 3PL sector, the electronic sector.

Tracking Serial Numbers in the Electronics Sector

Serial numbers play a significant role in fulfilment of electronics. Manufacturers, distributors, and retailers of electronics can track down defective items using serial numbers to identify the specific parts that are at fault.

Furthermore, keeping track of warranty information is crucial for an online merchant within electronics. Offering free services on products with expired warranties or allowing returns of the incorrect product when serial numbers are not properly tracked can cost businesses a lot of money. On the other side, by declining to provide servicing for goods that still have a valid warranty, they could seriously harm consumer satisfaction.

byrd's Software: A Powerful Solution for Your Inventory Management

The use of technology is without a doubt essential to inventory management. You can have good automatic control over it with the help of byrd's inventory tracking system. Our dashboard provides you with simple and efficient management to help you expand your business successfully.

Using our all-in-one fulfilment solution, you can add serial number tracking for your B2C shipments by merely adding (or modifying) products to your inventory and filling out the serial number tracking attribute in our dashboard. The warehouse staff scans the serial number of each product when it is time for shipping to ensure that the consumer receives the right item. With the use of our returns portal, you may also monitor returns to the warehouse.

Simply said, you can trace any item in your inventory from the time it is manufactured until it is sold with byrd's serial number tracking service. By giving your company access to vital information about the locations of your products, this feature lets you relax knowing that order fulfilment traceability is properly taken care of.