How to Calculate and Reduce Fulfillment Cost-Per-Shipment in European E-Commerce

Table of Content

If you run an e-commerce brand in Europe, you need to know exactly how much it costs to ship every order. Looking only at revenue is risky. Your cost-per-shipment (CPS) can show you which products make money and which slowly eat into your margins.

This guide will help you calculate CPS, understand where your money goes, and find ways to reduce these costs. All tips are tailored to European e-commerce brands.

Why CPS Is So Important for European E-commerce

- Profit per region

Selling in multiple countries is common in Europe. But shipping costs, VAT rules, and returns can vary by country. CPS shows which markets and which products are truly profitable. - Avoiding hidden cross-border costs

Many brands underestimate customs, duties, or failed deliveries, especially when shipping to the UK or other countries outside the EU. CPS highlights these extra costs so you can react. - Better decisions about fulfillment

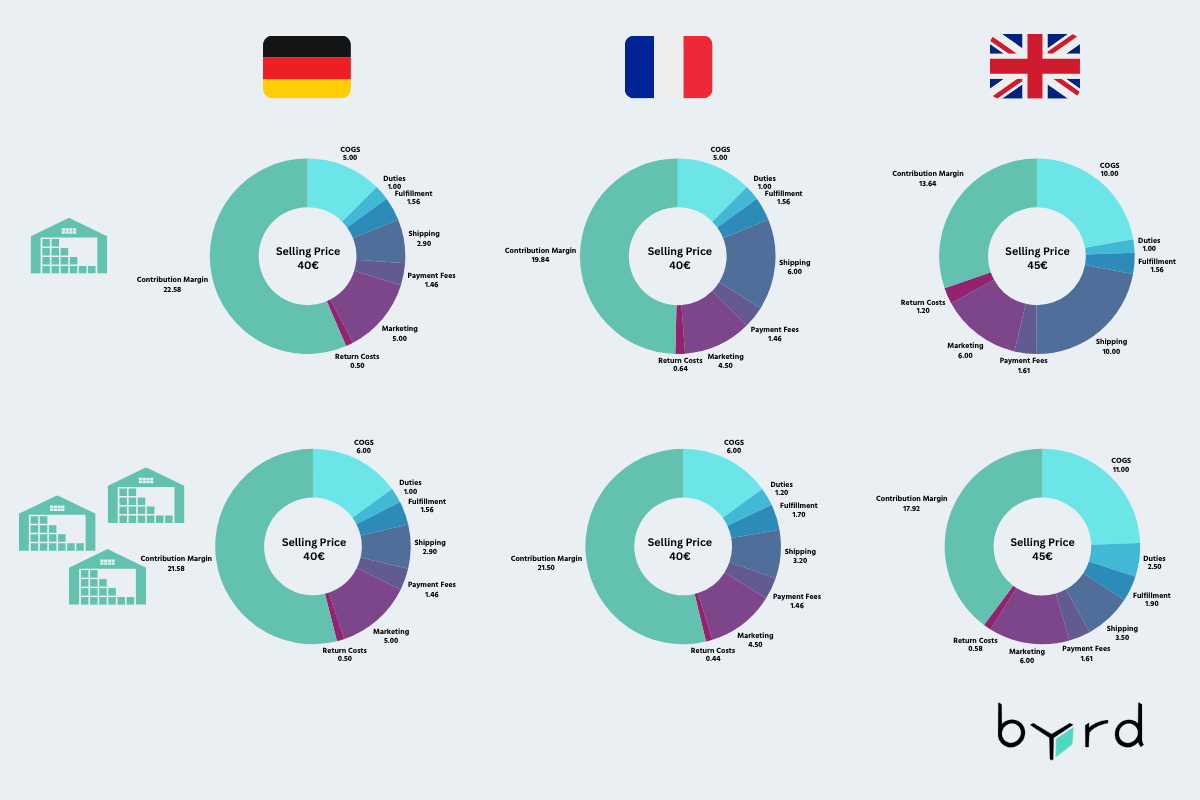

With CPS, you can decide whether to store products in one central warehouse (for example, in Germany or in France) or use multiple local warehouses.

How to Calculate CPS: The Six Cost Pillars

Use this basic formula (note that this is a basic calculation and does not include positions like HR inputs, equipment, building costs, maintenance, and security, which are specifically relevant for in-house logistics)

CPS per SKU = COGS + Fulfillment + Shipping + Platform Fees + Marketing + Returns

Get a copy of a basic CPS calculation sheet here

Below is a step-by-step breakdown with realistic examples.

Product Cost (COGS)

COGS (Cost of Goods Sold) is the total cost of producing or purchasing a product, including manufacturing, materials, and any costs to get it to your warehouse.

Example:

- Manufacturing cost per unit: €5.00

- Shipping from China to EU warehouse: €0.80 per unit

- Customs duties (4% on €5): €0.20

Total COGS: €6.00 per unit

💡 Expert Tip: If you’re purchasing from Asia (e.g., China), negotiate with suppliers for better bulk pricing. Alternatively, use EU-based suppliers for faster, sometimes cheaper, and more sustainable supply chains in general.

Fulfillment Costs

Covers everything that happens in the warehouse before the order leaves.

Typical costs with a 3PL:

- Pick base price: €0.76 per order

- Pick per item: €0.16 per item (assumption 1.5 per order -> 0.24€)

- Packaging material (box, tape, filler): €0.22

- Packaging workload: €0.24

- Label printing: €0.10

Total Fulfillment Cost: €1.56 per order

💡 Tips to reduce fulfillment costs:

- Use standard packaging sizes to reduce material costs.

- Work with a 3PL partner that fits your needs and product portfolio

Shipping Costs

This is, in general, the biggest cost driver for most brands.

Example for a 1kg parcel in Germany:

- Domestic shipping: €2.90 with DHL Kleinpaket

- Cross-border (Germany to France): ~€6.00

If you ship 1,000 orders to France every month, storing stock locally in France (domestic shipping price ~€3.20) could save €2.80 per order, or €2,800 per month.

💡 Tips to reduce shipping costs:

- Place stock closer to customers (multi-warehouse strategy).

- Avoid oversized packaging to reduce dimensional weight fees and “air commerce” -> shipping literal air.

- Optimize packaging material and size to fit shipping options with competitive rates, such as Warenpost International or DHL Kleinpaket.

- Use a multi-carrier setup to find the best shipping rates by location and product type.

Platform and Payment Fees

These are small per order, but add up.

Example:

- Marketplace commission (Zalando or Amazon): ~10-15% of selling price

- Shopify + Stripe/PayPal: ~2.9% + €0.30

For a €40 product sold via Shopify:

- €40 x 2.9% = €1.16 + €0.30 = €1.46 per order

💡 Tip to reduce fees:

- If possible, push more sales to your own store where you pay lower fees compared to marketplaces.

Marketing Costs

This includes paid ads, influencer fees, and discounts.

Example:

If you spend €5,000 on Google Ads and get 1,000 orders:

- €5,000 ÷ 1,000 orders = €5.00 marketing cost per order

💡 Tip to improve CAC:

- Track which countries have high organic sales to reduce paid ads there.

- Use fast shipping and smooth returns options as a selling point to boost organic conversion rates.

- Benefit from higher retention and positive word-of-mouth by investing in top-quality products and logistics

- Focus on a clean CRM setup to increase marketing efficiency

Returns and Refunds

Returns are high in Europe; depending on the industry, they can be a dealbreaker.

Example:

- Return rate: 10%

- Return shipping: €3.50

- Inspection and restocking: €1.00

- Damaged goods write-off: €0.50

At 10% return rate: (€3.50 + €1.00 + €0.50) x 10% = €0.50 per shipped order

💡 Tips to reduce returns costs:

- Add local return points to cut cross-border return costs.

- Offer size guides, better product descriptions, and photos or AI tools to reduce returns.

- Reduce carrier-caused returns with address validation features and proactive communication

Simple CPS Example

Let’s put it together for a skincare product sold and shipped for €40 in Germany:

- COGS: €6.00

- Fulfillment: €1.56

- Shipping: €2.90

- Platform Fees: €1.46

- Marketing: €5.00

- Returns (10% rate): €0.50

Total CPS: €17.42 per order

Contribution Margin: €40 - €17.42 = €22.58

If CPS rises to, let's say €20 or €25, profit shrinks fast. That is why continuous monitoring is key.

How to Use CPS to Improve Your Fulfillment

Cut the biggest cost drivers first

As shown above, shipping is usually one of the biggest cost factors in the supply chain. Getting things right will have an instant impact on your bottom line, while at the same time, it’s a key factor for the user experience and satisfaction.

Compare countries and SKUs

- Run CPS per region. A product profitable in Germany may be unprofitable in the UK due to high shipping and return rates.

- Stop selling or reprice SKUs with very low margins.

Track CPS monthly

- Use a simple CPS spreadsheet like this one and enhance and refine for your case.

- Set alerts if CPS increases more than X% month-on-month.

Next Steps

- Create your own CPS table for each SKU and region

Start with 5 top-selling products and your 3 biggest markets. - Run a fulfillment cost audit

Compare in-house vs. 3PL. Many brands cut shipping costs by 20 to 40% by switching to regional 3PLs. - Experiment with packaging and carrier options

Even small changes can save €0.50 to €1.00 per order.

Final Word

Understanding CPS gives you control over your margins. It helps you see where every euro goes and where you can save. Brands that monitor and optimize CPS regularly can offer faster shipping, keep prices competitive, and still stay profitable.

Visit our website to learn more about byrd's shipping and fulfillment prices.