Finding the Right Temperature-Controlled Warehousing Partner

Table of Content

The main idea of working with a temperature-controlled warehouse is that perishable products can be stored accordingly and sensitive products can be protected. If the products are stored under the right conditions, the perceived quality will also match the customer's expectations, which will prevent customer dissatisfaction.

There are several types of temperature-controlled warehouses, and in this article we want to provide you with helpful information to find the right temperature-controlled warehousing partner.

What is Temperature-Controlled warehousing?

While the definition might seem obvious, you might be surprised at all that it entails. A temperature-controlled warehouse is a facility dedicated to the storage, preparation and shipment of products that must be kept at a specific temperature.

The levels of temperatures managed in the warehouses are as follows:

- Ambient temperature: from 15°C to a maximum of 30°C

- Cool: between 10°C and 15°C

- Refrigerated: between 0°C and 10°C.

- Frozen: between -30°C and 0°C

What goods need a temperature-controlled supply chain?

The main sectors of products that need to be inside of a temperature-controlled warehouse are:

Food and beverages

Without the proper storage that can adequately protect food and beverages the bacteria, in a matter of minutes, can damage their quality. According to the U.S. State Food Safety, bacteria need three conditions to grow: food, moisture, and warmth.

PharmaceuticalsHigh humidity and drastic temperature changes can alter the composition of many of the components used to manufacture drugs. For this reason, the European Pharmacopoeia recommends the following temperatures for warehouses storing pharmaceuticals:

- Deep-freeze: below -15°C

- Refrigerator: 2°C to 8°C

- Cold or cool: 8°C to 15°C

- Room temperature: 15°C to 25°C

Chemicals

For safety reasons, chemical storage is extremely strictly regulated with regard to temperature.

Cosmetics

At high temperatures, cosmetics may be damaged. The tricky part about such products is that if they get damaged, you don't notice it immediately, as they may still look the same, but the quality simply deteriorates; the same goes for medical supplies and vaccines.

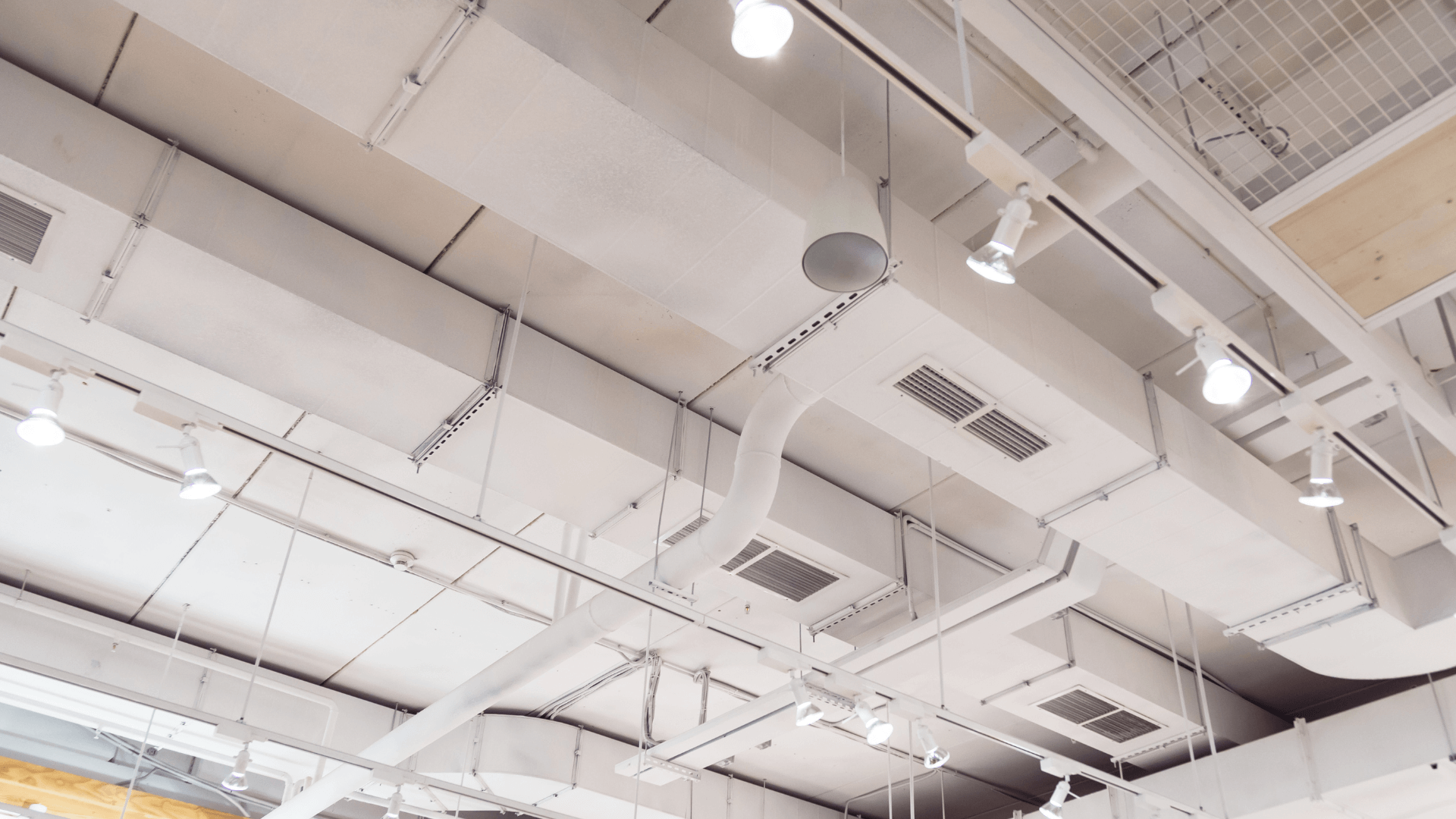

Building materials are key for fulfillment centers

Whether the warehouse only needs containers, refrigerators or the entire warehouse to be at the same temperature, it is important to have the right material to meet this goal. In order for the product to be preserved in the right way, warehouses must be designed with special systems. For example, to control the temperature difference between inside and outside, refrigeration equipment is placed at strategic points in the warehouse. Many warehouses add insulating elements at the walls with the goal of stopping temperature transfer to the outside.

Temperature-controlled warehouses typically require automated fulfillment processes, which at the same time can lead to operational efficiency improvements. The reason is that product loading in extremely cold or hot spaces cannot be performed manually by warehouse workers.

Aspects to take into account when looking for the right temperature-controlled warehousing partner

The choice of storing your products in a temperature-controlled warehouse depends on many factors. Starting from the type of products that would be stored, the space capacity of the warehouse, and the flow movements of the goods. Building materials and more elements are key to complying with safety standards and preserving product quality. Here we list key aspects to consider.

Temperature mapping

Temperature mapping is one of the main requirements that the warehouse has to do before installing all the necessary equipment such as shelves. In order to do a perfect temperature mapping the warehouse needs calibrated thermometers and sensors, also known as data loggers. They help to record and study the temperature and humidity in the warehouse. Once temperature mapping is completed, the warehouse can ensure that the storage installations are operating at temperatures that are safe for the products.

Air Quality

The quality of the air inside the warehouse also affects the quality of the product. If the temperature inside the warehouse is altered, dust, pests and external contaminants can enter. This could lead to damaged products that are sensitive to these elements. In addition, air quality not only protects the products, but also your workers. Keep reading to find out more about this last aspect.

Data loggers + Calibration Process

All devices work together to measure each other’s performances. Specific "calibrators" are used to measure the data logger's efficiency. This process is needed in order to complete the validation process. Which is necessary because warehouses need to stick to a validation plan to provide high quality data by the data loggers regularly.

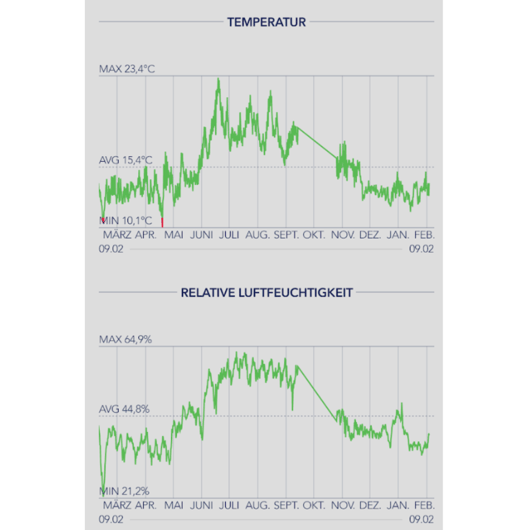

In addition to that, data loggers measure and store all information related to temperature and humidity in the warehouse. So by having all this information stored in a device, a warehouse can have all the data of a year in one place and analyze it. This is important to maintain high quality standards and take action if needed.

A dedicated team

All thermometers, data loggers and more devices may be in place, but as it happens, they can sometimes fail. Having regular checks or experts in the warehouse is essential to control the quality of the product.

Temperature-controlled warehousing with byrd

byrd's vast international network of warehouses, enables us to also offer temperature-controlled warehousing to our merchants. Our operations experts make sure that those maintain the expected quality by doing regular checks. On top of that, specialists also visit our facilities to check that the devices needed are installed in the right place. With internal and external audits we make sure that we don't have deviations in the calibration process.

If you're interested in temperature-controlled warehousing for the fulfillment of your products, which also helps to preserve your products longer in good condition, then request a quote today. Our fulfillment experts will be happy to help you out!