Lot Tracking Explained

Table of Content

Keeping track of inventory is crucial for any e-commerce business wishing to optimize its inventory turnover rates and tied-up capital. In the e-commerce supply chain, having a good tracking system in place is especially important for products that require more specialized storage and tracking. This is key specifically for products that can expire or can be potentially recalled.

A possible way to organize your inventory is Lot Tracking. It allows you to trace where batches of products came from and where they’re stored.

One of the key advantages of Lot Tracking is that you can easily optimize your cross-border fulfillment. By working with a fulfillment partner (like byrd) you can split up your inventory across multiple warehouses and still be able to comply with regulations. At the same time, you can keep track of which and at what time your products were produced, stored, and shipped.

Lot Tracking enables users to track so-called batches along the entire supply chain with the help of identification labels. Lot Tracking thus enables the tracking of products from the supplier, across storage in a logistics center, all the way to shipping and receipt by the end customer. As such, Lot Tracking helps you achieve an end-to-end overview.

In simplified terms, the process works as follows:

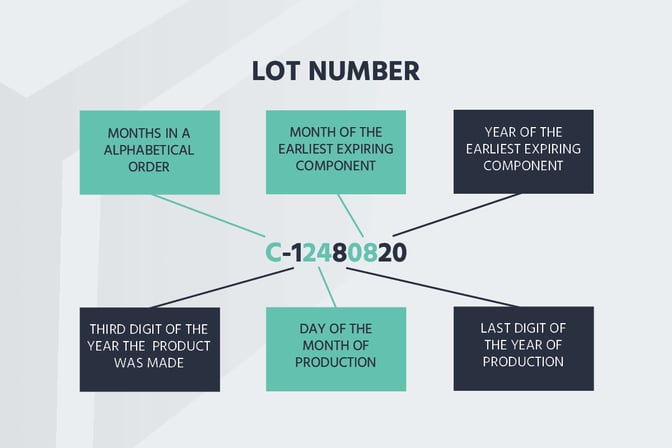

ID numbers are attached to parts of the goods during production. These Lot Numbers are either applied to the products themselves or to the packaging. Lot Tracking software then uses these numbers to track the individual steps of a batch.

What is the difference between Lot Numbers, SKUs, and Serial Numbers?

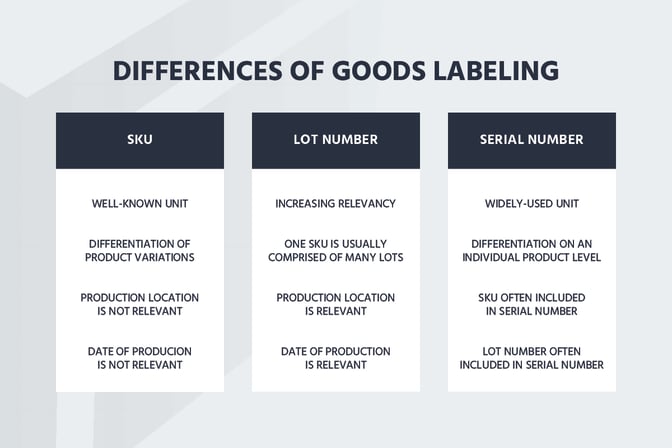

Properties of SKUs (Stock Keeping Units):

- One of the best-known units in logistics

- Differentiation of product variations (e.g. color, type, size)

- Production location is not relevant

- The date of production is not relevant

- The default SKU is between 8-12 characters long

To explain the use of SKU, let’s take a look at the example of a T-shirt. So, if you have a black T-shirt in 3 sizes (S, M, and L) each size has its own unique SKU, in our example, that means 3 SKUs in total.

Furthermore, if you then add a different color option (for example green) then we are already talking about 6 SKUs in total (that is, 3 different SKUs for the black T-shirt in S, M, and L, and 3 different SKUs for the green T-shirt in S, M, and L), as different color counts as a different item as well.

In terms of SKUs, it does not matter whether these products were manufactured and sold at the same location or at the same time.

Properties of Lot Numbers

- Relevance has been increasing

- One SKU usually consists of many lots

- Production location is relevant

- Production date is relevant

So let’s look at the prior T-shirt example again. As a reminder, we talked about T-shirts in 2 colors and 3 sizes (6 SKUs). It is important to note that the place or time of production has no influence on the number of SKUs. Lot Numbers, on the other hand, do make a distinction based on these characteristics. Thus, the SKU black T-shirt in size M, for example, can consist of several lots and thus be assigned to different Lot Numbers.

Properties of Serial Numbers:

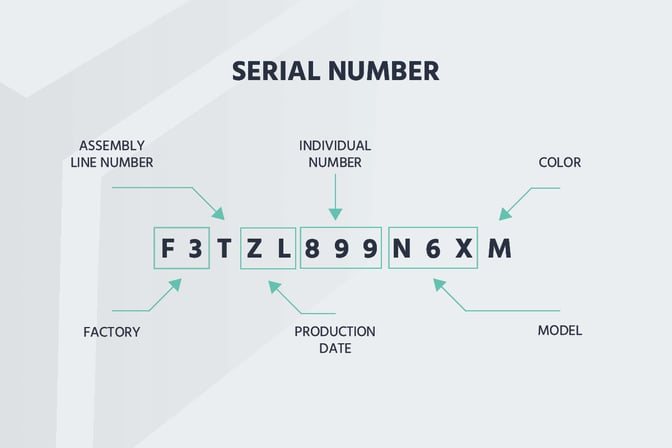

- Widely used unit

- Differentiation on an individual product level

- SKU often included as part of the serial number

- Lot Number often included as part of the serial number

So while SKU and Lot Number bundle goods into groups, the serial number identifies each product. In our example, each T-shirt has its serial number, which often includes SKU and Lot Number. You can think of it as the social security number, which also contains the respective birthday, but can still be assigned to each person individually.

Lot tracking is an essential method for controlling processes, remaining operable at all times, and responding quickly to changing or problematic circumstances. When it comes to product recalls or warnings, for example, accurate tracking enables a fast and straightforward process. That can prevent negative consequences in the best possible way.

In addition, accurate Lot Tracking is also crucial for optimizing inventory management. This way, you always have an overview of your warehouse and can further increase the efficiency of your supply chain and order fulfillment.

For example, Lot Tracking enables or simplifies the use of the so-called FIFO (first-in-first-out) principle. This logistics strategy means that products that were put into storage first are also shipped first.

Having this process in place will minimize the risk of your products exceeding their expiration date. Furthermore, lost profits and additional costs for disposal of products can be prevented, while your company can align better with the trend of sustainable e-commerce by preventing unnecessary waste in the supply chain and inventory management.

Last but not least, having Lot Tracking and FIFO processes in place will also rule out the accidental shipments of expired products. This will render your business safe from negative feedback, lodged complaints, and dealing with legal recourse due to selling and shipping out-of-date products.

This approach is specifically important for perishable products or goods that generally run the risk of expiring. For this reason, batch tracking is a crucial prerequisite for FDA/ISO/CFIA certifications, in short, this is the prerequisite for BIO certification for your products. In addition, the origin of the products can be traced through the entire supply chain, thus confirming the title “organic”.

Batch tracking is particularly relevant for e-commerce companies in the following industries:

- Food, drinks, and nutrition

- Biological products

- Expirable products

- Potentially hazardous industries

- Medical or pharmaceutical products

In the areas mentioned, the use of Lot Tracking software is often regulated by law. However, its use also makes sense in most other industries and helps to improve processes in nearly every industry.

By combining our warehouse partners and our state-of-the-art warehouse management software (WMS) with Lot Tracking and FIFO processes, our customers benefit from smart and automated processes that minimize human errors and improve the whole order fulfillment process. No matter if storage, pick and pack, or shipping, we make the entire fulfillment process efficient, transparent, and flexible.

E-commerce fulfillment companies like byrd use Lot Tracking to streamline the fulfillment process, minimize errors, and ensure product quality during order fulfillment.

For example, in our dashboard, you can assign a Lot Numbers to specific items that are stored in our fulfillment centers. When products are put into storage, the relevant batch numbers are scanned and can be viewed in your inventory dashboard which means that inventory can always be viewed in real-time. The items with assigned lot numbers will be stored in separate locations, according to their lot number.

In addition, byrd uses the first-in, first-out (FIFO) inventory allocation process that is designed to identify shelves that contain items with an expiry date first and always ship the nearest expiring lot date first.

Conclusion on Lot Tracking

In summary, Lot Tracking is a vital factor for both, improving your inventory management and optimizing your order fulfillment process. Furthermore, Lot Tracking is essential in enabling the profitable sale of certain products, such as organic items. It also allows for greater transparency and safety in the event of unexpected problems that may lead to recalls or product warnings.

To conclude, there is no way around Lot Tracking, especially for e-commerce companies that sell perishable or dangerous goods. The arguably easiest way for ensuring optimized Lot Tracking combined with cross-border fulfillment is to partner up with a 3PL company like byrd, and benefit from the streamlined order fulfillment processes, international fulfillment network, and state-of-the-art inventory management software.